-

MenuBack

-

Kategórie

-

-

-

Elektrobicykle

-

-

-

-

-

-

-

-

-

-

-

RÁMY

-

-

-

-

-

-

Ráfikové Brzdy

-

Vychytávka

-

-

-

-

-

-

-

-

Kolesá

-

-

-

Plášte

-

-

-

Vložky / Inserty

-

-

-

-

-

-

Odpružené vidlice

-

-

-

Tlmiče

-

-

-

-

-

-

-

-

Posed

-

-

-

Sady

-

-

-

-

-

Príslušenstvo

-

-

-

-

-

-

-

-

Rider Gear

-

-

-

-

Značky

Filtruj podľa

-

-

Značky

- 77DESIGNZ

- absoluteBLACK

- ARC8

- BOSCH eBike

- BrakeSTUFF

- DT SWISS

- DVO

- EARLY RIDER

- ERGON

- EVIL BIKES

- EXT Extreme Racing Shox

- FAZUA

- FOX

- GALFER

- INDUSTRY NINE

- INTEND

- LOOSE RIDERS

- MAGURA

- MAXXIS

- NEXTIE

- OAK COMPONENTS

- RENTHAL

- REVERSE Components

- RISK Titanium

- SANTA CRUZ

- SB ONE

- SHIMANO

- TRICKSTUFF

- TUNE

-

-

-

EVIL BIKES

EVIL BIKES

-

-

-

Rámy a Framesety

-

-

-

Náhradné diely EVIL

-

-

-

MAGURA

MAGURA

-

-

Výrobcovia

-

- Výpredaj ZĽAVY AŽ DO 60%

- Bazár pozri

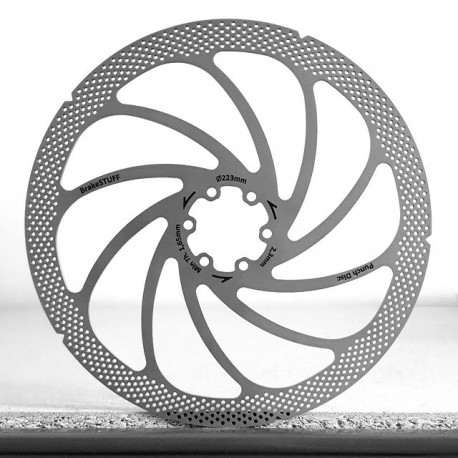

BrakeSTUFF PUNCH Design 220mm 2,15mm Brzdový kotúč

IS220-Punch-2,15

Nový produkt

2 ks ks

Skladom

Pozor: Posledné kusy na sklade!

NASKLADNENIE cca:

| Odberné miesto DPD / Alzabox | utorok 31. 12. 2024 |

| DPD Kuriér | utorok 31. 12. 2024 |

| DPD CZ/PL/AT/HU | štvrtok 2. 1. 2025 |

Tabuľka dát

| Priemer | 220/223 mm |

| Uchytenie kotúča | 6 dier (IS2000) |

Detaily

Brzdový kotúč BrakeSTUFF PUNCH Design - uchytenie na 6 skrutiek (IS2000) - heat treatment* - glass bead blasting**

Prémiový kotúč nemeckej výroby od inovátorskej firmy BrakeSTUFF v spoluprácu s INTEND BC.

Materiál: High alloy stainless steel ( AISI 420 C)

Custom výroba (na mieru) v akomkoľvek priemere (120mm, 140 mm, 160mm, 180mm, 203mm, 220mm, 223mm) a hrúbke (2.00mm, 2.15mm, 2.30mm) (a pokojne aj s vyfrézovaným menom)

Výroba kotúčov BrakeStuff PUNCH je až 6x časovo náročnejšia ako výroba bežného kotúča, čo sa prejavuje aj na vyššej predajnej cene.

Z celkového hľadiska sa Vám však investícia vráti v podobe predĺženej životnosti samotného kotúča (*heat treatment) a nižšej spotreby brzdových platničiek.

Okrem tepelnej úpravy má výrazný vplyv na životnosť kotúča zvolená hrúbka (vs. Shimano/Sram 1,8mm - min. wear 1,55mm):

2,00mm - 1,6x dlhšia životnosť (o 60%)

2,15mm - 2,4x dlhšia životnosť (o 140%)

2,30mm - 3,0x dlhšia životnosť (o 200%)

Pozn.: Všetky súčasné brzdové strmene rôznych výrobcov bŕzd môžu použiť kotúče aj o hrúbke 2,30mm

Výhody PUNCH Design:

- o 30% viac efektívnej brzdnej plochy oproti klasickým konkurenčným kotúčom - maximálna brzdná sila

- 777 mini dierovaní na brzdnej ploche výrazne predlžuje životnosť brzdových platničiek (čím väčšie diery, tým kotúč viac "žerie" platničky)

- vynikajúca teplotná odolnosť/kapacita (pohlcovanie tepla a rýchle ochladzovanie)

- nízky fadingový index - odďaľuje zavädnutie brzdového systému.

- heat treatment - tepeľná úprava predlžujúca životnosť kotúča, i jeho ceľkovú pevnosť a rovnosť po prehriatí

- glass bead blasting treatment - mechanická povrchová úprava skracujúca čas potrebný na "zabehnutie" kotúča

- dizajnovaný na extrémnu záťaž, určené aj pre eBike, eMTB a gravity disciplíny, Zjazd

- kompatibilný s kotúčovými brzdami všetkých značiek.

Hmotnosť: viď nižšie

Priemer 220mm s deklarovaným 10% zvýšením brzdného výkonu oproti 203 mm kotúčom pri rovnakej sile vyvynutej na páčku.

Obsah balenia: 1ks brzdový kotúč vrátane 6ks oceľových skrutiek (T25)

MADE IN GERMANY

Width of the braking surface

Ø140 mm = 14 mm

Ø160 mm = 14,5 mm

Ø160 mm (Punch Light) = 14 mm

Ø180 mm = 16 mm

Ø180 mm (Punch Light) = 14 mm

Ø190 - Ø203 mmmm = 16 mm

Ø220 - Ø223 mm = 17 mm

Weight

Ø120 mm = 75 g

Ø140 mm = 98 g

Ø160 mm = 125 g

Ø180 mm = 155 g

Ø180 mm (Punch Light) = only 129 g !

Ø180 mm = 170 g (Thickness: 2,15 mm)

Ø203 mm = 192 g (Thickness: 2,00 mm)

Ø203 mm = 214 g (Thickness: 2,15 mm)

Ø203 mm = 229 g (Thickness: 2,30 mm)

Ø220 mm = 260 g (Thickness: 2,15 mm)

Ø223 mm = 283 g (Thickness: 2,30 mm)

Compatible with

- Magura

- Shimano

- Trickstuff

- TRP

- AVID / SRAM

- Formula

- Hayes

- Hope

Description

Mechanical brake test according to DIN EN ISO 4210-2: 2015-12 and velotech.de Q2015 standard passed with top values

Made from stainless steel which is hardened then ground flat, for a long lasting rotor with perfect trueness. Compatible with all major brake brands, just make sure the outer diameter is correct and the correct caliper adaptor is fitted

Brake surface with many small holes to increase the effective area to absorb and dissipate the heat generated during braking ➔ 30% more surface area compared to a comparable standard brake disc

654 holes in the Ø180 mm and 777 holes in the Ø203 mm version

less wear of the brake pads due to many small holes in the brake surface

*Information for the heat treatment:

For additional stability and strength, all our disc brakes are heat treated. During this process, basic strength in addition to the resilient properties of the material can be improved. As a result, our discs have a very high level of strength, and visibly lower wear, which gives the discs a longer life! In addition, the risk of bending the disc is reduced, so your disc should stay straighter, longer!

These effects are only visible when the disc is installed correctly, and the brake is used properly.

**Information for the glass bead blasting treatment:

The glass bead blasting is a mechanical surface treatment, which is perfectly suited for achieving an equal, uniform. Scale and initial colors of the pre-heat treatment are safely removed after this process. The surface is thereby not only cleaned, but also easily compacted, thereby increasing the resistance to stress corrosion cracking. The blasting material used is absolutely ferrite-free.

This method has the advantage that the braking time significantly decreases compared to conventional brake discs and thus the full braking force is available quicker.

In addition, another pleasant side effect is that the the brake discs now have sharp edges coming from production, and the whole aesthetics are improved. In the area where the brake pad rubs on the wheel, the normal grinding pattern is produced.